Supply Chain Management Center

Innovation from product development to delivery

The route from point A to point B and then to point C might look like a straight line. But with supply chains, there’s always a way to quicken the pace, conserve costs and better anticipate risks.

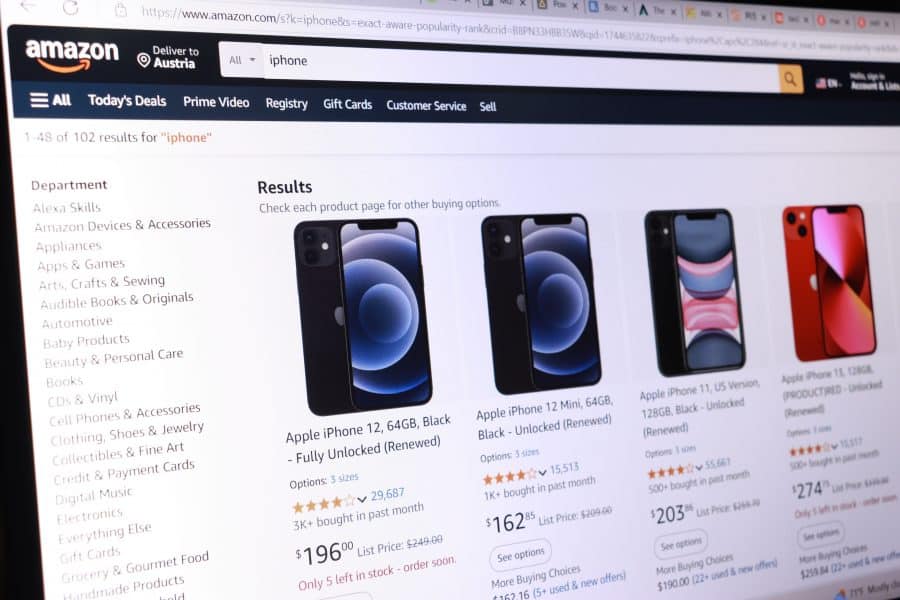

Factors from artificial intelligence, the Internet of Things, and data to agile manufacturing, customization, and traceability continue to overhaul how goods are made, managed and shipped to retailers. The University of Florida Warrington College of Business’ Supply Chain Management Center keeps on top of these advancements by contributing insights from our research, exchanging ideas with professionals and encouraging our students to drive the field’s progress.

This approach all adds up to ready-to-apply solutions tailored to specific processes and stages. See how we’re setting a new standard for tomorrow’s supply chains.

About the Supply Chain Management Center

As a nexus for the supply chain industry, our center ignites important discussions between leaders, scholars and students. These connections enhance our awareness of ongoing challenges and prompt us to investigate them through research and student projects.

Networking

Learn who our students are (and all they can do) as they learn about the supply chain industry’s workings directly from its leaders.

Board of directors

The professionals influencing our center’s activities reflect all sides of the field: logistics and transportation, warehousing, retailing, sourcing and procurement, and investing, with representation from consumer goods and food to healthcare.

Supply chain research

“Better” takes a number of directions along a supply chain — more detailed data gathering, real-time adaptability, and strategies to limit interruptions and product defects — that we define through research that yields more concrete recommendations.

Healthcare information exchanges

We found that profits rise for these systems — intended to improve healthcare delivery by offering rebates when members purchase directly from suppliers — when more patients participate.

Interdependent components

With a focus on automotive manufacturing, we examined product quality in relation to internal production and outsourcing from multiple suppliers, finding that controlled interdependence correlates with increased part integrity.

Product variety

This study highlights how companies can take advantage of cost-effective decoy brands in a similar yet price-diverse market to increase sales and profits.

Perishable products and displays

To address waste reduction, our researchers proposed display strategies that engage supermarket customers through discount prices and simultaneously move older inventory.

Blood banks

Supply uncertainty and inefficiencies can raise healthcare costs for patients. In response, our study suggests ways hospitals can align expectations for blood supply and quality with available resources and subsidies.

Green products

How easy (and economical) is it to go green? This study assesses the return on investment of sustainable materials and waste management in manufacturing in relation to market diversification and expansion.

Cross-market supply chain mergers and acquisitions

Researchers analyzed these patterns on market share and their effects on independent competitors.

Experiential learning program

Why chase change when you can be on the cutting edge of supply chain innovation, courtesy of the students enrolled in Warrington’s Master of Science in Information Systems and Operations Management program? As a participating partner, you can present a problem and nurture future professionals as they design a novel strategy from the ground up.

The goal: Make a case for an advanced product, process, or technology that targets a company- or supply chain-related concern. MS in Information Systems and Operations Management students then spend four to six months researching, testing and finalizing their ideas.

Devoting three to four hours per week to the project helps students develop a more customized solution that your team will be able to implement upon the project’s completion.

Among recent projects, our students developed a prescription drug tracking and identification system for Southeastern Groceries, harnessed machine learning to predict customers’ payment habits based on credit history for J.B. Hunt Transport and helped UF Health Shands Hospital more accurately evaluate fill rates across different clinical units.

Related programs

Across three distinct concentrations, MS in Information Systems and Operations Management students prepare to spark organizational progress at the intersection of technology, data and industry objectives.

Student experience

“The ELP project with J.B. Hunt gave us the opportunity to consult with a $8.6B revenue company and work on their business data. Through the project, we have gained a valuable perspective on analyzing and solving business problems using data science and analytics techniques. Thank you again for providing us such an amazing learning experience.”

Yu-chon (Tom) Wang (MS ‘20)

Get involved

Ready to recruit? Interested in sponsoring a project or research? Here’s how you can join the discussion or find your next hire.

The latest news

Upcoming events

Contact us

Supply Chain Management Center

Warrington College of Business

University of Florida

Stuzin Hall 333

1454 Union Rd